Molten Metal Handling / Foundry Ladles

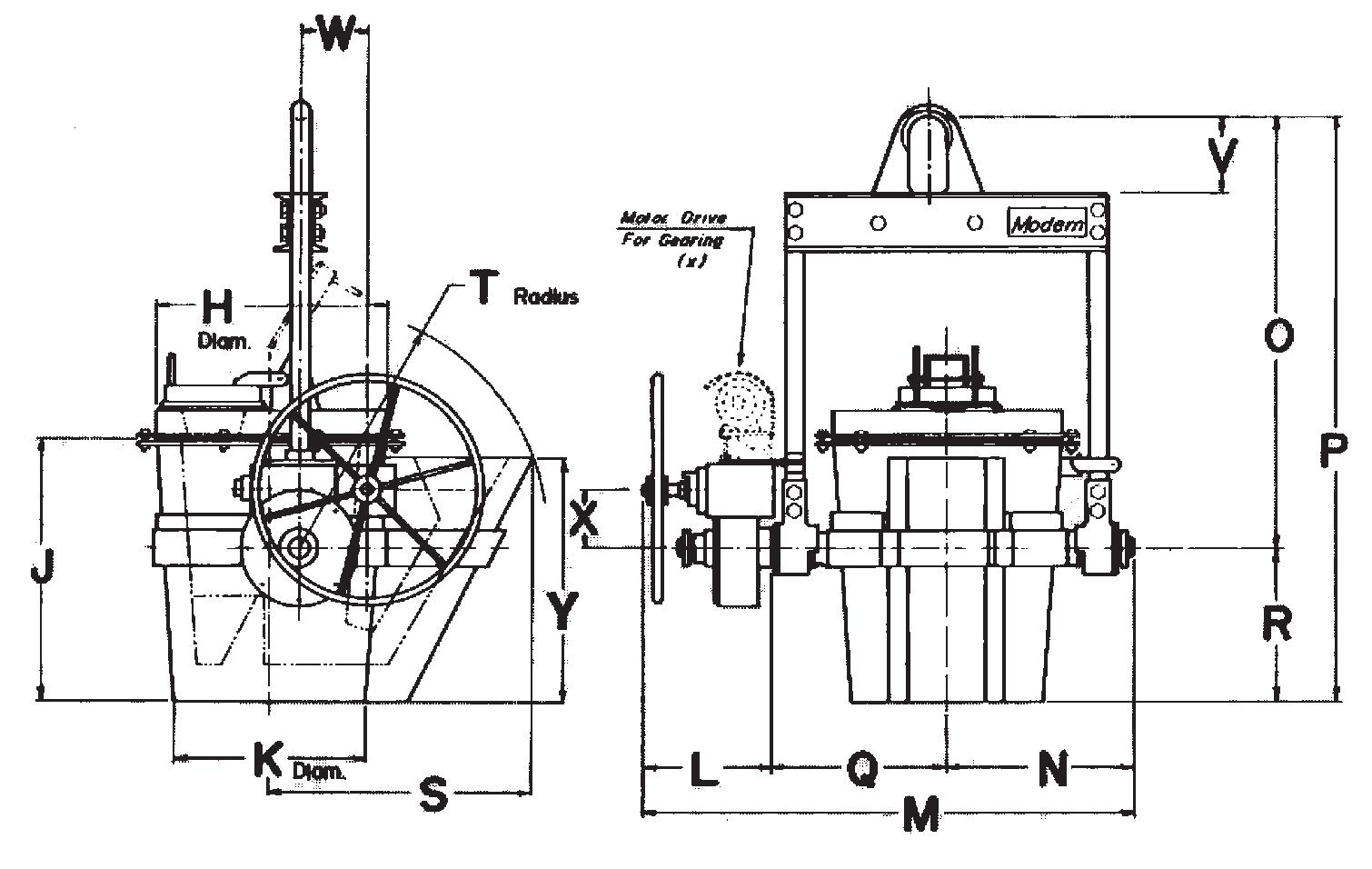

View Diagram Specifications

Dimension H: 24 to 49 in

Dimension J: 31 to 63 in

Dimension K: 20-1/2 to 42 in

Dimension L: 10-7/8 to 19-1/2 in

Dimension M: 47-1/2 to 89-1/2 in

Dimension N: 19-1/8 to 36 in

Dimension O: 50 to 93 in

Dimension P: 68-1/2 to 125 in

Dimension Q: 17-1/2 to 34 in

Dimension R: 18-1/2 to 32 in

Dimension S: 27 to 52 in

Dimension T: 28-1/2 to 58-1/2 in

Dimension V: 5-1/2 to 20 in

Dimension W: 5-3/4 to 16-1/4 in

Dimension X: 5 to 20-1/4 in

Dimension Y: 27-1/2 to 60 in

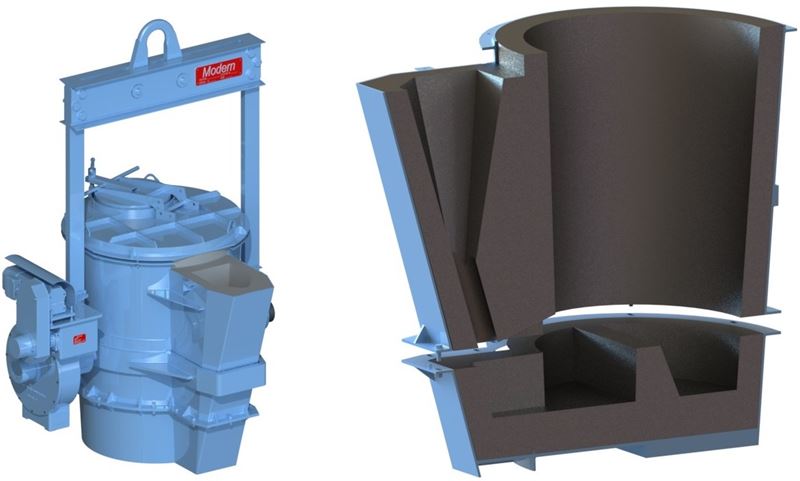

Series 1189 Mod-Tundish Ladle

The Most Efficient, Economical Pour-Over Inoculation System Developed

No.1 Type (Lever) Shanks

The Mod-Tundish® Ductile Iron Treatment Ladle is industry-proven to minimize heat loss, provide uniform treatment, and minimize magnesium fuming with maximum recovery. A full outside teapot spout permits receiving, faster pour-out, and minimizes tramp inclusions in treated metal. Also, it’s ideal as a distribution ladle – minmizing temperature loss.

Ask about our Mod-Tundish® Ductile Iron Treatment Ladle today!

Maximum Recovery, Minimum Escape of Magnesium Fumes.

SIZE LINING

CAPACITY

BOTTOM LINING

Split Bottom Design Available

FREE TOP SPACE

CONTACT US

FEATURES

Dimensions as listed are approximate and may vary with application.

All-steel fabricated sectionalized lining forms are available for Mod-Tundish® ladles.

This treatment ladle is manufactured under U.S. Patent No. 4,509,979.

Select split bottom design for ease of maintenance.

Series 1000 Covered, Tapered Ladles

No.1 Type (Lever) Shanks

Covered tapered ladle with No. 1 type lever shank and detachable ball.

Series 1010 Tapered Open Ladles

No.1 Type (Lever) Shanks

Open tapered ladle with No. 1 type lever shank, roller bearing trunnions and detachable bail.