Molten Metal Handling / Foundry Ladles

Pouring Device with Hand-Wheel Control

Handling hot-metal loads that extend beyond the range of hand-shank pouring demands the efficiency of MODERN geared Pouring Devices.

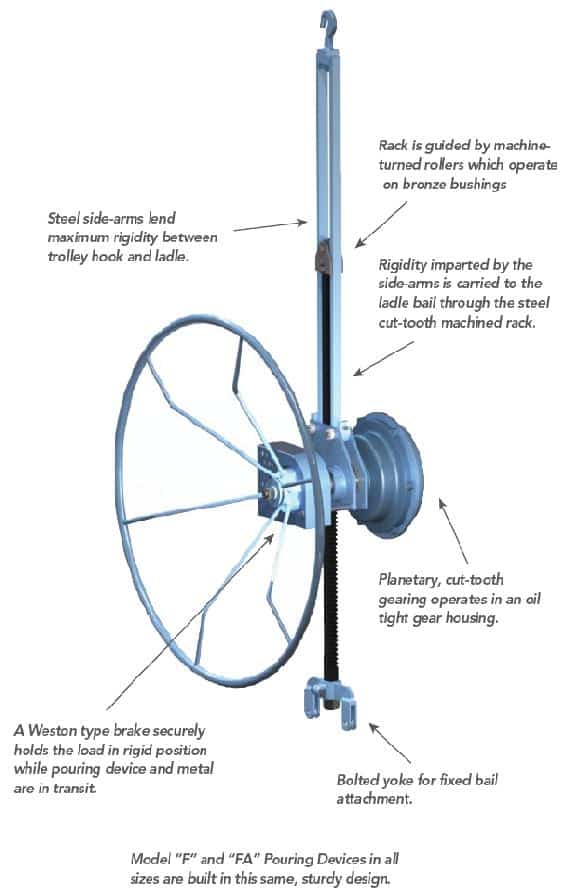

The large hand-wheel and efficient planetary gear system, as illustrated, relieves the pour-off-men of much back-breaking-work. Geared lifting of the molten metal affords maximum safety, too. A Weston type brake holds the ladle at any desired height. Turning the handwheel in a clockwise’ direction raises the load. Turning counter-clock-wise quickly inches the load to its accurate lowered position over the sprue. Each machine is thoroughly tested. Moving parts are effectively guarded against the damaging effects of dust, shot and heat.

In every detail there’s nothing better than a MODERN geared Pouring Device. It’s the original in the field! The two most popular models shown on the following page are widely accepted as standard throughout the foundry industry.

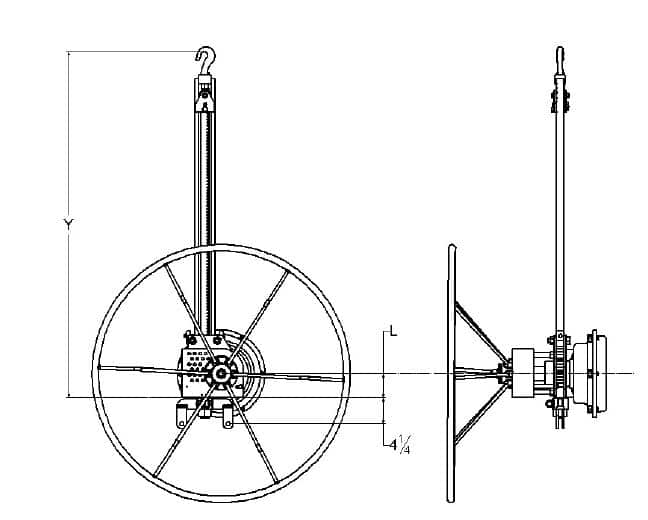

Model “F” and “FA” Pouring Devices in all sizes are built in this same, sturdy design.

Model “F” Pouring Device

MODERN Model “F,” geared Pouring Devices are good general purpose machines for pouring molds. Gross loads totaling 650 pounds are transported with minimum effort. The severe working conditions of foundry operation were taken into account in the design of the Model “FA.” Planetary cut-tooth gearing operates in an oil-tight gear case. Weston type load brake and steel ladle lock guard the safety of the operator. The range of lifting heights is shown in specifications listed on this page. The “F” and “FA” devices are available with either the bolted clevis or hook yoke.

Model “FA” Pouring Device

The “FA” Pouring Device is the heavy duty manually operated unit. It is designed to handle gross loads of 1500 pounds. In addition to its popular application for pouring floor-molds the model “FA” is widely used over monorail systems for disturbing metal to the smaller pouring ladles.

Series 1000 Covered, Tapered Ladles

No.1 Type (Lever) Shanks

Covered tapered ladle with No. 1 type lever shank and detachable ball.

Series 1010 Tapered Open Ladles

No.1 Type (Lever) Shanks

Open tapered ladle with No. 1 type lever shank, roller bearing trunnions and detachable bail.