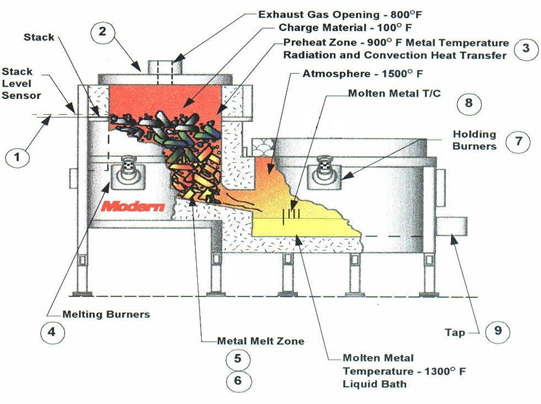

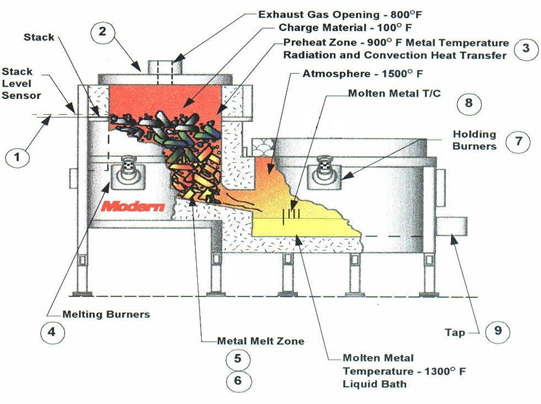

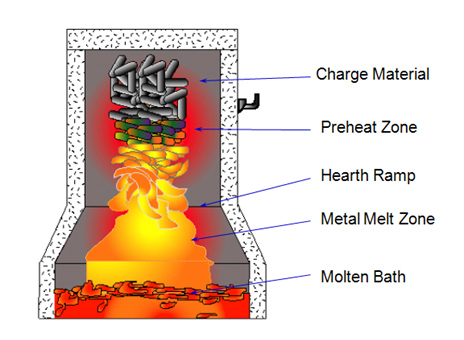

Basics of Stack Melting

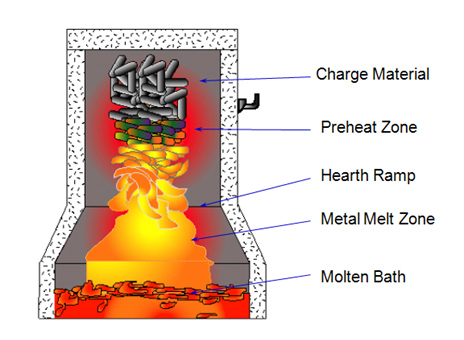

Aluminum shaft, or stack furnaces are now widely accepted as a modern operational and sound financial choice because of their higher energy efficiency than of the reverberatory furnace. The stack melter efficiency is improved by better sealing of the furnace and the use of the flue gases to preheat the charge materials. The charge materials slide down the shaft and reach the melting zone where they are melted by the burners, and the molten metal flows down to the holding area. The hot exhaust gases from the melting zone flow through the shaft to preheat the incoming charge, improving the energy efficiency of the stack furnace by 40 to 50%. Melt loss is also dramatically improved from 4-8% in a reverb, down to 1% or less in a well operated stack melter.

Jet Melter® Stack Detail

Back to Top

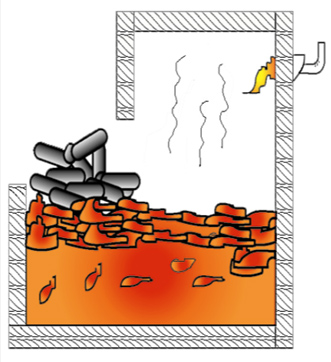

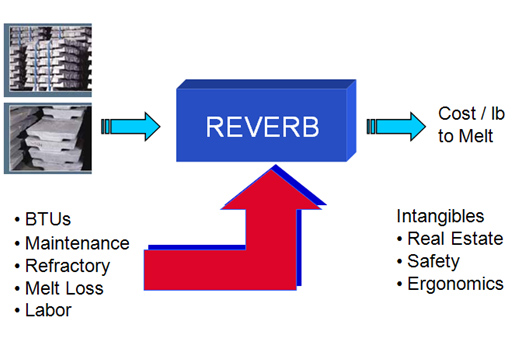

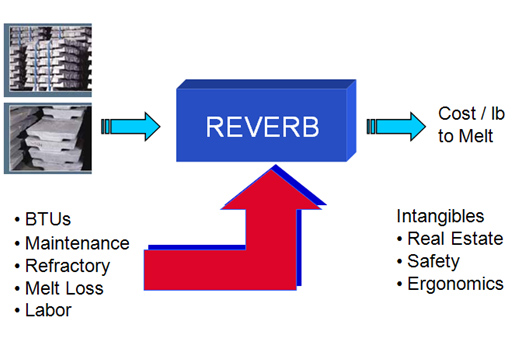

Reverb Melting Disadvantages

Reverb Furnace Problems

Poor Thermal Efficiency - Only 25%

Accelerated Dross Formation - 3% to 7%

Large Metal Temperature Variations +/- 50º F

Higher Inclusions Levels

Larger Bath Required To Melt Aluminum

Greater Hydrogen Gas Pick Up

Reverb Cost Variables

Back to Top

Technology Comparison Chart

A Clear Green Option, The Real Financial Choice

Comparison Data

Fuel Consumption (Btu/Lb.)

Thermal Efficiency (%)

Metal Loss (%)

Refractory Cleaning

Refractory Life (years)

Charging System

Bath Capacity to hourly melt rate ratio

Molten metal Temp. variation

Noise Level

Jet Melter®

900 - 1000

45 - 55

0.7 - 1.5

Once per day

5 to 8

Semiautomatic or Automatic

2.5 : 1

± 10° F

< 85 dba

Reverb Furnace

1500 – 3000

24 – 32

3 – 7

Once per day

2 to 4

Manual or Semiautomatic

10 : 1

± 50° F

> 90 dba

Back to Top

Actual Comparison of Melter Performance

(Side by Side Test Results)

Melt Loss

Energy Usage

Molten Metal Temp. Control

Metal Specific Gravity

Metal Cleanliness K-Value

Jet Melter®

0.9%

955 Btu#

± 5° F

2.26

0.0

Reverb

5.5%

1975 Btu#

±32°F

2.10

0.10

Alloys added for chemistry adjustment

Back to Top

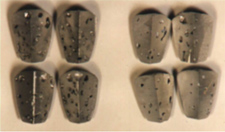

Melt Quality Comparison

10:50 AM - S.G. = 2.16 11:50 AM - S.G. = 2.26Modern Jet Melter®

Gas Samples

11:07 AM - S.G. = 2.10 12:12 PM - S.G. = 2.10Reverb Melter Gas

Samples

Back to Top

Estimated Payback Analysis

Melting Costs ** Typical 2000 #/hr (1 shift operation)

- ASSUMPTIONS

- UNITS

- JET MELTER

- REVERB

- Melt Loss

- percent

- 1%

- 4%

- Aluminum Cost

- $ per pound

- $ 1.20

- $ 1.20

- Energy cost

- Average $ per therm

- $ .32

- $ .32

- Energy usage

- Btu's per pound melted

- 1000

- 2000

- Aluminum Usage

- Pounds Melted per Month

- 333,333

- 333,333

- COST TO MELT PER POUND

- $0.0032

- $0.0064

- ENERGY COST PER MONTH:

- $1,066

- $2,133

- MELT LOSS COST PER MONTH:

- $4,000

- $16,000

- TOTAL MELT COST PER MONTH:

- $5,066

- $18,133

- MONTHLY SAVINGS

- $13,067

Melting Costs ** Typical 2000 #/hr (1 shift operation)

- ASSUMPTIONS

- UNITS

- JET MELTER

- REVERB

- Energy Cost

- Average $ per therm

- $.32

- $.32

- Energy Usage

- Btu's per pound held (assumed)

- 50

- 50

- Amount Held

- Pounds Held

- 5,000

- 20,000

- Holding Period

- Hours held monthly

- 533

- 533

- COST TO HOLD PER MONTH

- $426

- $1,706

- MONTHLY SAVINGS

- $1,280

- TOTAL MONTHLY SAVINGS (Melt & Hold)

- $14,347

9 Reasons Why: Stack Melter Technology Beats Traditional Reverb Furnaces

- Improve safety due to limited exposure to molten metal and pre-heating of the charge material

- Floor space reduced due to 2.5x holding capacity versus 10x

- Efficiency of 1,000 Btu per pound versus 2,500 Btu

- Lowered holding costs caused by 2.5x holding capacity versus 10x in a reverb

- CO2 emissions lowered (less gas burned = less CO2)

- Lower melt loss (1% vs.3-8%)

- Improved process control and resulting metal quality caused by only a +/- 10 degree F holding temperature variation versus large swings each time a cold charge is placed into the hot bath

- Improved process control and resulting metal quality due to reduced gas levels created by more stable temperatures and reduced burner fluctuation and reduced surface area within the bath

- Reduced manpower requirements with automated charging systems vs. manual charging exposing operators to metal splash.

Back to Top

Why Buy Modern Equipment?

- Designed and Manufactured in the USA

- Project Capabilities from Design to First Melt

- Complete Turnkey Solutions

- Spare Parts Readily Available

- On Site Service and Technical Support

- Over 120 satisfied installations and repeat customers! The clear industry leader!

Get more details or contact us for a complementary ROI assessment:

Loren Tieman

National Market Manager

262-957-7940

ltieman@moderneq.com