WE KNOW

celebrating 100 years

LADLES

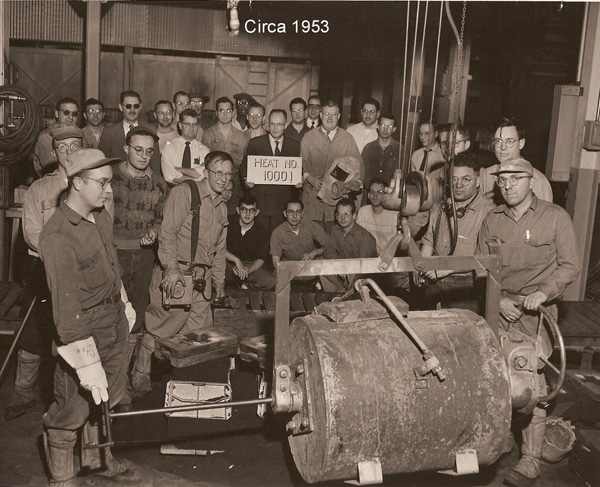

At Modern Equipment, we have been building industrial ladles for molten metal material handling for over 100 years. We have probably built and rebuilt more ladles than many of our competitors combined.

MODERN EQUIPMENT CASE STUDY

Read more ›

FREQUENTLY ASKED QUESTIONS

Read more ›

WHY BUY FROM MODERN EQUIPMENT?

Read more ›

About Modern Equipment Company

CONSISTENT QUALITY SINCE 1919

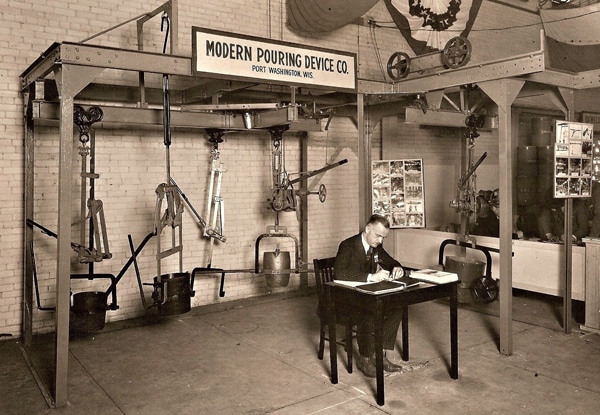

Modern Equipment started in business in 1919 with a small line of ladles and pouring devices developed by founder Max Goldberg, and was originally known as The Modern Pouring Device Company.

The business moved into the iron and steel foundry business and introduced the Hot-Blast Cupola to the industry in the 1940’s. As aluminum casting began to take center stage in the 1980’s, Modern licensed and further developed Stack Melt technology for the North American market, and positioned itself as the market leader for these systems. Modern has engineered customized ladling, handling and melting solutions for customers both in North America and worldwide.

#thinkMODERN

Foundry Ladle Manufacturing Solutions

Our Services

At Modern Equipment we have been building ladles for many industries, for over 100 years and have clients worldwide. We also rebuild ladles and supply wear and spare parts for our ladles.

At Modern Equipment, safety is critical.

We build many ladles for the American and the Canadian market. We are currently building ladles with improved 10 X safety requirements of this demanding market.

WHAT SETS US APART

Why buy ladles from modern equipment?

our industry mix makes us better

At Modern Equipment we build industrial ladles (from X to Z for size) and across many different metals and products. We build ladles for steel plants, ladles for gold refineries, silver smelting, aluminum and crucibles for magnesium. We have even built tar material handling ladles for the roofing industry.

LOWEST COST OF OWNERSHIP

We do not claim to be the cheapest ladle manufacturer, and may be on the premium side when it comes to pricing. What is striking to us is when a customer calls us with questions for a ladle that we made 30, 40 and even 50 years ago!

SERVICE AND SUPPORT

Ladle maintenance is critical to the longevity, safety and efficacy in manufacturing. We offer maintenance and spare parts to our supplied equipment.

LARGE INSTALL BASE

OUR KNOWLEDGE BASE

YOU’RE IN GOOD COMPANY

Our customers use our ladles in many different configurations: custom and standard ladles, for ferrous & non-ferrous applications and we also produce foundry-proven gearboxes.